Rate Testing System Material Fatigue

"Reduce your overall cost and improve your production process with your own Material Fatigue and/or Rate Testing Systems"

- Reduces cycle test-time through intelligent automation

- Improves test accuracy and repeatability

- Scalable to any most testing requirements

- Maximizes personnel resources

- Reduces the reliance and cost of subcontracted testing

- Keeps proprietary property in-house

Fully Automated Test Cycle

- Static & Dynamic Test Cycles

- Reduces Test Cycle Time

- Eliminates Inconsistency of Manual Testing or Subcontractor Issues

- Remote Access Capability and Control Station

- Interfaces with Remote Databases for Test Parameters and Data Logging

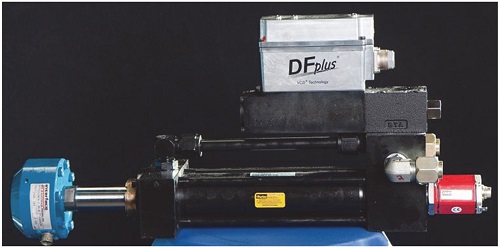

These Highly Precise and Complex Systems Usually Consist of:

- Delta Motion Controllers

- DFP Valves

- MTS Temposonic,

- Interface Load Cell

- Touch Screen

- Hydraulic Power Units

- Cylinders

Increased Quality and Productivity

- Reaches Specified Pressure Rapidly and Accurately

- System Over-Pressure Protection Reduces Potential Pump and Valve Failure Repair Time

- Decreased Test Time

- Closed Loop Control Can Overcome Overshooting

- Operator Training/Deployment is Greatly Reduced

For one customer of leaf springs or golf carts, the manufacturing process starts with high-carbon, high-alloy spring steel. The springs are heat treated, formed, quenched, assembled and then painted.

To insure product quality, a number of springs are tested on a fatigue testing system on a daily basis. The system will vary the force in a sinusoidal manner accruing cycle counts as it proceeds.

This customer has since incorporated some automation to improve speed and flexibility along with more diagnostic information. The implementation of a "smarter", more flexible closed-loop controller returned dividends of twice the testing speed, improved testing repeatability and reliability and has also expedited the customers product development process.