Electronic Cooling System using any Oil Type

Controlling and Monitoring the heat load on high performance, liquid cooled, electronics is the issue being addressed with Wilson Company Electronic Cooling Systems.

These Electronic Cooling Systems can incorporate precision pressure, precise temperature all incorporated with compensated flow controls calibrated to very low flow rates. Temperature sensors incorporated into the test equipment along with precision turbine flow meters and pressure transducers allow for sensing of in/out flow rates, in/out temperatures and fluid pressure all of which can be collected and displayed in REAL TIME on a touch screen along with remote viewing via an internet connection.

A typical system, using a PAO fluid, will run at 100 PSI to cool to electronics and will be able to control the flow rate between 0.3 and 1 GPM all along monitoring the temperature going into and out of the electronics. Also most designs have the ability to monitoring the flow rate in #/hr or GPM into and out of the electronics.

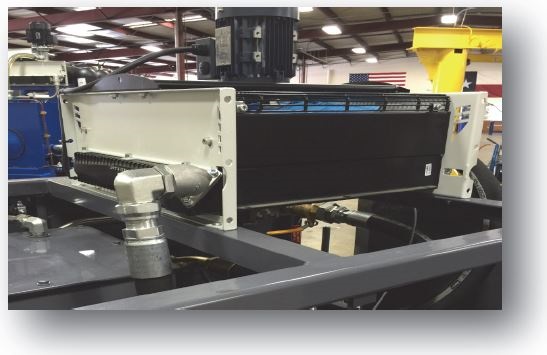

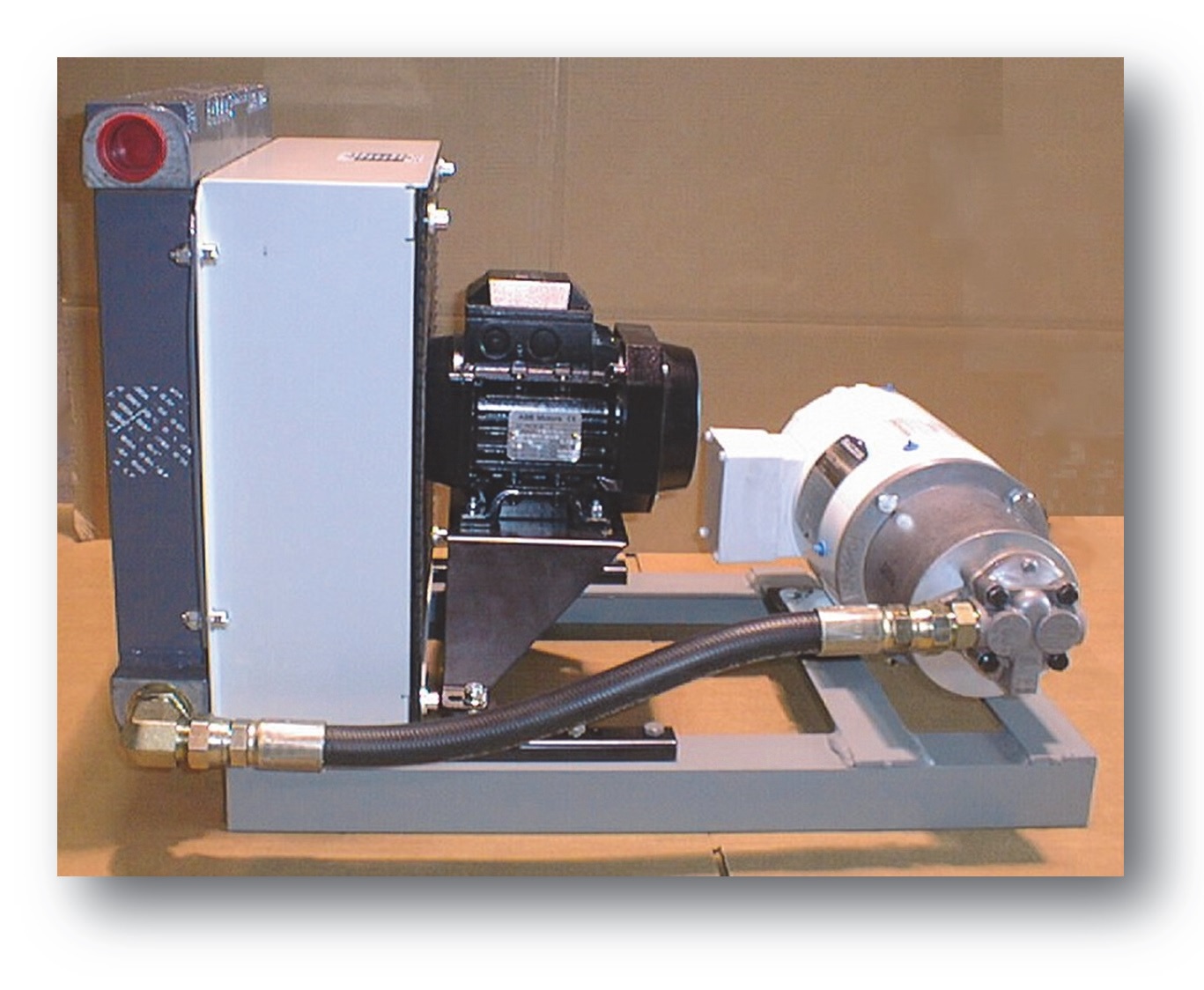

Designs can be as simple as a pump/motor with a cooling fan to a large complex systems with redundant filtration, heavy monitoring and highly automated.

"Simple to Complex Electronic Cooling Systems"

- Greatly improves the oils lifecycle

- Allows for cleaner, longer lasting and more reusable oil

- Protects gears from varnishing due to high oil temperatures

- Protects seals from braking down

- Reduces moisture due to large changes in temperature

- Extends the life of the oil

- Extends the life of any gear box

Components and Function

- Air / Oil cooler fan driven

- Wash down motor

- Gear Pump; Moves oil from gear box through cooler, Optional oil filter

- Temperature Switch; Control the cooler fan to regulate the oil temperature